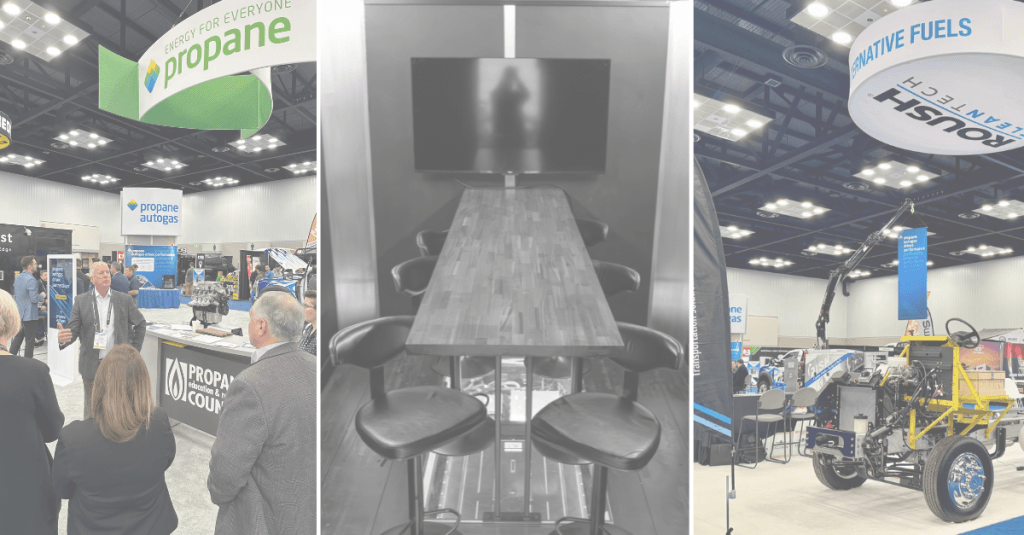

Work Truck Week (WTW), hosted annually by the National Truck Equipment Association (NTEA), was held this year from March 4-7, 2025, in the Indiana Convention Center in Indianapolis, Indiana. While the week featured informative sessions by knowledgeable speakers on a wide variety of work truck topics, one of the highlights of the week for many attendees was the exhibit hall. The massive space inside the convention center allows for vehicles of all shapes and sizes, including semi truck cabs, chassis, delivery trucks, and more. Beyond vehicles, there are also many vendors selling work truck-related technology.

Some of the most interesting exhibitors to speak to were ones focused on alternative fuels and sustainability, as they are at the forefront of the clean transportation frontier. We spoke with a handful of exhibitors who either manufacture and carry clean fuel vehicles or provide products or services that support them, asking about their business operations and experience at Work Truck Week.

Propane Education and Research Council

Transitioning to propane-powered vehicles is a strategic move for many fleet operators, school districts, and commercial businesses looking for sustainable and cost-effective fuel alternatives. But how does one navigate this shift successfully? That’s where expert guidance comes in from the Propane Education and Research Council (PERC), which helps buyers connect with propane vehicle providers, establishes the necessary infrastructure, and offers ongoing education and support throughout the process.

“My first goal is to find out what they want to accomplish,” says Joel Stutheit, Senior Manager of Autogas Business Development, when asked how the partnering process begins. “Understanding the unique needs of each buyer is essential in tailoring solutions that meet their operational and sustainability goals.”

A prominent part of PERC’s strategy is connecting buyers with vehicle providers by working closely with suppliers like ROUSH CleanTech and the Alliance AutoGas network to ensure access to high-quality propane-powered vehicles. It also involves infrastructure assistance, such as helping customers understand and implement the necessary fueling infrastructure for their propane vehicles. Ongoing education and resources play a crucial role, with webinars, training sessions, and educational materials ensuring informed decision-making. Lastly, continuous support remains a priority, with ongoing involvement to address challenges and facilitate a smooth transition. PERC provides all of this.

One way to build interest is by showcasing real-world applications. Events like Work Truck Week provide an opportunity to demonstrate how propane is being used in practical settings, such as fueling EV chargers, powering crane trucks, and supporting school bus and paratransit fleets.

While battery-electric vehicles (BEVs) are gaining momentum, many believe a multi-fuel approach is essential. “There’s a big push for BEV, and we think there’s a place for that, but we have to have a multi-fuel approach,” says Bridget Kidd, COO of the Propane Education & Research Council (PERC). “Renewable and conventional propane can help users meet emission standards.”

PERC’s involvement spans multiple industries, from agriculture and material handling to commercial transportation. Innovations such as EV chargers powered by propane for backup or prime power highlight the versatility of this fuel. With increasing interest in low-emission alternatives, propane continues to be a viable solution for many sectors. By working closely with buyers, suppliers, and infrastructure providers, the transition to propane-powered vehicles can be seamless and rewarding. Whether for school buses, paratransit services, or corporate fleets, propane offers a sustainable, efficient, and cost-effective fuel choice for the future of transportation.

PERC has returned to WTW for 23 years to make valuable connections and stay updated on the latest advancements in propane technology.

ROUSH CleanTech

ROUSH CleanTech continues to play a pivotal role in the adoption of propane as a sustainable fuel solution for commercial vehicles and school buses. Unlike aftermarket conversions, ROUSH CleanTech provides dedicated propane fuel systems that integrate seamlessly with multiple makes and models, including Ford commercial vehicles and Blue Bird buses.

With an exclusive contract through 2030, ROUSH CleanTech is the manufacturer of propane fuel systems for Blue Bird’s buses, ensuring high-quality, factory-installed solutions. ROUSH CleanTech collaborates with Blue Bird dealers across all 50 states and Canada, working directly with them to sell propane-powered school buses in their territories.

Their team actively engages with school districts by setting up meetings, organizing ride-and-drive events, and visiting transportation directors and service managers. These interactions allow decision-makers to experience the benefits of propane buses firsthand, including lower fuel costs, reduced maintenance, and improved emissions performance, especially in cold weather. It also will provide propane fuel systems for Blue Bird’s upcoming commercial chassis.

For maintenance teams, the transition to propane is seamless. Diesel technicians can easily service propane vehicles with minimal additional training. ROUSH CleanTech offers web-based training modules, onsite instruction, and factory workshops to ensure mechanics are well-equipped to maintain these vehicles.

Beyond school buses, ROUSH CleanTech serves a wide range of commercial fleets. Companies in the food and beverage industry, including Absopure Water, Nestlé water (Blue Triton Brands), and Schwan’s Company, have adopted propane for their delivery fleets. Additionally, beer wholesalers, distributors, and USPS contractors rely on propane-powered vehicles for efficient and eco-friendly transportation.

Renewable propane is another exciting development in this space. ROUSH CleanTech systems are already compatible with renewable propane, though the focus remains on increasing supply availability. The environmental benefits of renewable propane make it an attractive option for fleets looking to further reduce their carbon footprint.

One of the key advantages of choosing ROUSH CleanTech is their commitment to quality and compliance.

“All of our propane systems are Environmental Protection Agency (EPA) and California Air Resources Board (CARB) certified and we maintain factory warranties and meet stringent emissions standards, including certification to .02 NOx,” said Chelsea Uphaus, Director of Marketing at ROUSH CleanTech. “Unlike bi-fuel systems, ROUSH CleanTech’s dedicated propane solutions ensure that fleets maximize the cost and environmental benefits of propane without the option of switching back to gasoline.”

Attending industry events like the Work Truck Week (WTW) has been a longstanding tradition for ROUSH CleanTech, with roughly 17 years of participation. The event provides an invaluable opportunity for networking, reconnecting with existing customers, and discovering new business prospects. ROUSH CleanTech saw strong booth traffic and had engaging conversations, particularly at the Green Truck Summit (GTS) portion of the event. With discussions shifting from a singular focus on electric vehicles to a broader range of alternative fuel solutions, ROUSH CleanTech feels well-positioned to contribute its expertise across multiple technologies, including hydrogen and electric propulsion systems.

As the industry evolves, ROUSH CleanTech remains dedicated to providing fleets with reliable, low-emission, and cost-effective propane solutions. Their continued presence at key industry events and commitment to innovation ensure they will remain at the forefront of sustainable transportation for years to come.

Fontaine Modification

Fontaine Modification has been a leader in commercial vehicle conversions for over 40 years, working closely with truck original equipment manufacturers (OEMs), dealers, and equipment suppliers to modify trucks after production. From engineering solutions to contract manufacturing, Fontaine Modification provides a full range of services tailored to various industries and applications.

One of the most common modifications is dual steer conversions. These involve taking a brand-new vehicle and modifying the interior to accommodate two steering positions—one on the left and one on the right—making them ideal for street sweepers and refuse trucks. Another common conversion is for auto-haulers, where the truck cab is lowered and reconstructed to allow an extra vehicle to be transported on top.

Fontaine Modification is also at the forefront of clean fuels and e-mobility. Traditional conversions include adding natural gas and propane systems to gasoline-powered trucks. However, Fontaine Modification is now also pioneering electric, hybrid, and fuel cell truck modifications, bringing advanced clean transportation technologies to market.

For alternative fuel solutions, Fontaine Modification takes a factory-built gasoline-powered truck and integrates a natural gas system, enabling it to run on natural gas, propane, or biodiesel. For BEVs and fuel cell electric vehicles (FCEVs), Fontaine Modification works directly with powertrain developers. One approach is converting a gasoline or diesel truck into a BEV or FCEV by removing the internal combustion components and integrating the new powertrain. Another method involves receiving rolling chassis from OEMs—trucks without powertrains—and installing complete electric or fuel cell powertrain systems.

Each fuel type has its benefits and ideal applications. BEVs work best for fixed-route operations, such as package delivery, shuttle services, and school buses. They have zero emissions, consume no fuel, and require lower maintenance. FCEVs offer similar benefits but have longer ranges and are less dependent on charging infrastructure, making them ideal for long-haul trucking and refuse collection. Hybrid electric vehicles (HEVs) integrate electrification without requiring extensive infrastructure, making them a good fit for high stop-and-start operations like refuse trucks, school buses, and delivery fleets. Meanwhile, compressed natural gas (CNG), propane, and biodiesel offer cleaner emissions for delivery and tractor fleets.

Fontaine Modification stands out in the industry due to its long-standing reputation, strategic locations near major truck OEMs, and cost-effective solutions.

“We’ve been well-established in the commercial vehicle space for over 40 years and have a broad range of experience and capabilities, as well as a full range of solutions,” said David Brosky, Director of Sales & Business Development for eMobility at Fontaine Modifications. The company’s expertise spans a wide range of vehicle classes (4-8) and powertrain modifications, and its engineering team has the capability to scale production as demand grows.

Fontaine Modification has been a participant at WTW for as long as the event has existed—25 years—and remains a member of the NTEA. The company continues to return to WTW because it attracts a diverse range of customers, including fleets, dealers, and equipment manufacturers. Attendees are highly knowledgeable about the work truck and commercial vehicle market, making it an ideal venue for industry engagement. Fontaine Modification also regularly contributes to the Green Truck Summit and is actively involved in the Green Truck Association (GTA).

As a member of Clean Fuels Michigan and a previous member of Clean Fuels Ohio, Fontaine Modification remains dedicated to advancing cleaner, more efficient vehicle solutions. Whether through alternative fuel conversions, electric powertrain integration, or customized truck modifications, Fontaine Modification continues to be a trusted partner in the commercial vehicle industry.

Bollinger Motors

Bollinger Motors is making a name in the electric chassis world with its purpose-built, commercial electric truck chassis. Choosing a Bollinger Motors chassis over other options comes down to design, engineering, and long-term usability.

Unlike many competitors that retrofit internal combustion engine (ICE) chassis for electric use, Bollinger Motor’s chassis is specifically made for electric power. As one of the biggest challenges with retrofitting ICE-based chassis is component placement, with many manufacturers placing batteries and electrical components externally, Bollinger Motor’s electric chassis allows the batteries and components to be securely housed inside the frame rails, similar to how a rib cage protects vital organs. This results in a more durable and resilient design and offers significant advantages in protection and servicing, both of which are especially important for commercial work trucks that undergo rigorous use.

Another key differentiator is upfitting. Bollinger Motor’s chassis features completely flat frame rails with no components above them. This unique design makes it easy to install a variety of upfits—whether a box truck, flatbed, or specialized equipment—without requiring significant modifications. Many competitors require adjustments to accommodate their chassis, whereas Bollinger Motors simplifies the process, making it more cost-effective and flexible for businesses.

Serviceability is another major advantage. Bollinger Motor’s design allows for easy access to key components, particularly the battery, which can be removed with just nine bolts. Unlike other electric trucks where accessing critical parts may require removing the upfit or extensive disassembly, Bollinger Motors ensures that maintenance and repairs are straightforward. This reduces downtime and lowers the total cost of ownership, making it a smarter investment beyond just the initial purchase.

Beyond serviceability, Bollinger’s chassis also enhances driving performance. Since it was designed from scratch as an electric vehicle, the battery weight is strategically centered and placed low in the chassis. This results in a lower center of gravity, providing better balance and a more confident driving experience. Additionally, Bollinger Motors’s unique Quad Bend design—where the frame rails taper in at the wheels and then back out—improves the truck’s turning radius and maneuverability, crucial for commercial drivers working in tight spaces. A cab-forward design further enhances visibility, making the truck safer and easier to operate.

Due to its unique design features, Bollinger Motor’s chassis is also very versatile.

“The chassis is super flexible in what you can use it for,” said Drew Bacheller, Director of Marketing at Bollinger Motors. “Some applications include a box addition to do any sort of delivery for daily routes under 200 miles. We have also had landscaping and construction companies. There are really broad use cases.”

Bollinger Motors is currently focused on bringing the B4 to market, ensuring it meets the needs of businesses looking for reliable, electric commercial vehicles. Looking past the B4, Bollinger Motor is working on its B5, launching next year, which will build on the B4’s solid foundation. While visually similar to the current B4, it moves from Class 4 to Class 5, increasing its payload capacity and making it suitable for a broader range of commercial applications.

Bollinger Motors has been attending Work Truck Week for roughly four years and recognizes WTW as the premier event in commercial trucking, as it’s where competitors, suppliers, and potential customers converge. Last year, Bollinger participated in the Ride & Drive event for the first time, giving prospective buyers a hands-on experience with their trucks. This kind of direct engagement helps ease concerns about electrification and provides a tangible understanding of Bollinger’s capabilities.

Work Truck Week continues to be a crucial event for Bollinger Motors, offering direct feedback from customers and partners while strengthening its position in the commercial EV market.

Work Truck Week Exhibitors Plan to Return in 2026

Work Truck Week 2025 once again provided ample opportunities to talk to experts and innovators in the work truck industry, in addition to delivering valuable insights for professionals, showcasing the latest trends, technologies, and strategies in the commercial vehicle sector. Anyone who attends can attest to the show’s expansive exhibit hall and wide variety of companies participating in the event. Anyone who is looking for something work truck related will surely find both ample knowledge and solutions, including those within the clean fuel vehicle and technology space.

Work Truck Week 2026, scheduled for March 10-13 in Indianapolis, promises another year of innovation, education, and industry collaboration. Learn more on the Work Truck Week website.