Biodiesel and renewable diesel come from a joint history but are ultimately two separate and distinct fuels with unique production processes. Perhaps the most important difference is that biodiesel meets the ASTM D6751 standard, while renewable diesel meets the ASTM D975 standard for petroleum diesel fuel. Together, these fuels fall under a fuel category commonly referred to as bio-based diesel or biomass-based diesel. This blog looks at how biodiesel and renewable diesel developed, how they’re made, and what sets them apart in performance and use.

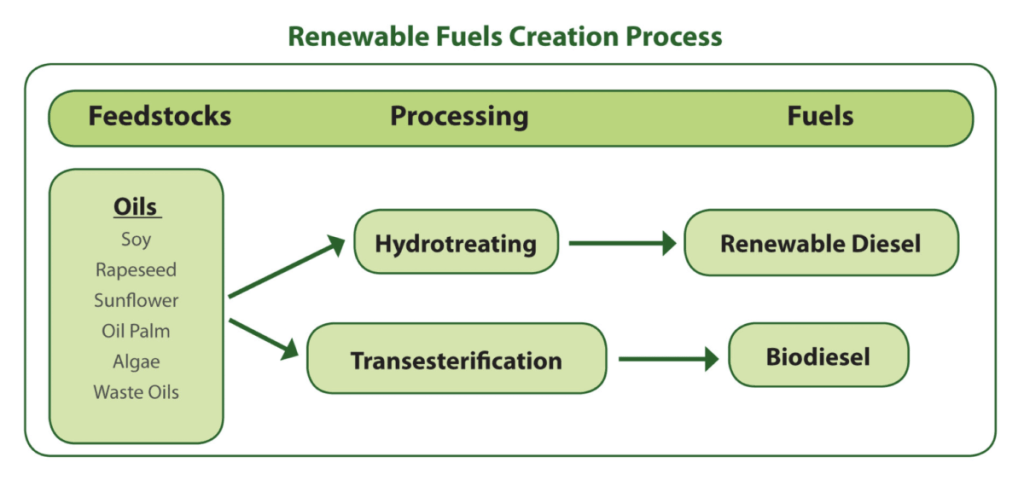

Source: Graphic provided by the B20 Club of Illinois.

The beginnings of biodiesel and renewable diesel

The creation of biodiesel and renewable diesel began at the same starting point more than a century ago. Rudolf Diesel, the German engineer who invented the diesel engine, demonstrated his invention’s ability to run on vegetable oils at the 1900 World Exhibition in Paris, using peanut oil as one of the first forms of biobased diesel fuel. His original engine design could operate on a variety of fuels, but after his death, petroleum quickly became dominant, and diesel engines were subsequently redesigned to run on petroleum diesel.

By the 1930s, researchers explored separating fatty acids from glycerin in vegetable oil to create a lighter fuel more comparable to petroleum diesel. In 1937, Belgian inventor Georges Chavanne patented an ethyl ester of palm oil, and by the following year, a passenger bus in Belgium was running on palm oil ethyl ester. During World War II, vegetable oils were occasionally used as fuel when petroleum shortages arose, though petroleum maintained its supremacy.

The modern biobased diesel movement gained momentum in the 1970s, following the oil embargo that drove many nations to seek alternatives. Straight vegetable oil, however, proved too viscous for contemporary diesel engines, prompting scientists to refine methods of converting vegetable oils and animal fats into usable fuel.

This research ultimately led to today’s production of biodiesel and renewable diesel. Both fuels are derived from fats and oils, but they are made through different processes: biodiesel through transesterification, and renewable diesel through hydrotreatment. These pathways result in two distinct fuels, each with its own unique properties.

What is biodiesel?

Biodiesel, also known as B100 or Fatty Acid Methyl Esters (FAME), is a renewable, non-toxic, biodegradable, low-carbon alternative to petroleum diesel meeting the ASTM D6751 standard. It is produced through transesterification, a chemical process that separates glycerin from waste oils, animal fats, and plant-based oils. The result is FAME, chemically similar to diesel fuel, along with renewable glycerin as a byproduct used in soaps, cosmetics, and other products. Biodiesel has historically been blended with petroleum diesel at various levels, most commonly at B20 (20% biodiesel), but blends such as B30 and B99/B100 are also being used more commonly as standards and quality have improved over time under the industry’s voluntary BQ-9000 program. Biodiesel, in its pure form (B100), is growing in popularity in engines designed or modified to run on it, as fleets look to decarbonize long-haul trucking, municipal operations, and more.

The U.S. biodiesel industry as we know it today was developed and expanded with strong support from soybean producers, and about 70% of production capacity is located in the Midwest. Commercial-scale production began in Kansas City, Missouri, in 1991, and adoption grew quickly after Yellowstone National Park and Saint Louis Lambert Airport successfully used biodiesel in vehicles and encouraged other fleets to follow suit. Today, the biodiesel industry maintains a production capacity of nearly 2 billion gallons, with production largely centered in the Midwest.

Due to its chemical properties, biodiesel’s cold weather performance varies depending on the blend ratio, feedstock, fuel additives, and characteristics of the petroleum diesel used as a blend stock. Although higher blends are more prone to gelling, fleets across the U.S. have reliably used biodiesel blends up to B20 in freezing conditions. Both petroleum diesel and biodiesel contain compounds that can crystallize in low temperatures, so understanding cloud point (the temperature at which wax crystals begin to form) and cold filter plugging point (the temperature at which crystals block filters and restrict flow) is critical for reliable operation.

Additives lower the cold filter plugging point (CFPP) and improve cold flow in several ways. The use of #1 diesel fuel, a thinner, premium-quality fuel designed for cold-weather use, can further improve flow and help to prevent gelling in cold temperatures. With the right preparation, fleets can confidently operate biodiesel blends year-round. Fleets can also upfit vehicles to operate on B100 with aftermarket or factory installed technologies.

What is renewable diesel?

Renewable diesel, also known as R100 or Hydrotreated Vegetable Oil (HVO), is a low-carbon alternative to petroleum diesel fuel that serves as a direct direct, drop-in replacement for petroleum diesel, usually requiring no modifications to engines or fueling infrastructure. It is most often produced through a hydrotreatment process, which is similar to the method used to manufacture petroleum diesel. This process also generates several valuable byproducts, including renewable propane and naphtha, the latter of which can be used as a building block for renewable gasoline and chemicals.

Chemically, renewable diesel differs from biodiesel in that it is a hydrocarbon fuel, not an ester. Because renewable diesel’s chemical structure is similar to petroleum diesel, it also meets ASTM D975, the same standard that applies to petroleum diesel. This means renewable diesel can be used as a standalone fuel in nearly all diesel engines without blending or engine modification requirements.

Renewable diesel production in the U.S. first emerged in the early 2010s, when Tyson Foods helped establish the first large-scale renewable diesel facility in Louisiana with animal fats serving as the primary feedstock. Over the next decade, renewable diesel production expanded, with production capacity expected to reach more than 5 billion gallons annually in 2025. Renewable diesel production capacity is heavily concentrated along the Gulf Coast, which accounts for about 60% of the nation’s renewable diesel output.

One of the advantages of renewable diesel is its stability in colder conditions. However, cold weather can still impact renewable diesel performance and reduce fuel economy. While renewable diesel produced for winter operations can resist gelling more effectively than biodiesel, renewable diesel will freeze into a solid block if stored close to its cloud point, which is typically around -10°C (14ºF). To address this, producers and fuel users rely on the Freezing Point test, which measures the temperature at which the fuel solidifies and establishes safe handling and storage limits under cold conditions.

Cold-weather performance of renewable diesel is also shaped by how it is produced. A key factor is the extent to which paraffins are isomerized during refining. This process influences the cloud point of the final product, and since different producers use different methods, renewable diesel can vary in its cold-weather operability. Most U.S. producers adhere to pipeline specifications and seasonal guidelines to manage these variations, but the lack of consistent standards across regions means customers may encounter renewable diesel with different cloud point characteristics depending on location and season.

Blending biodiesel and renewable diesel

While biodiesel and renewable diesel are notably distinct fuels with different production processes and characteristics, fuel producers, marketers, and end-users have long recognized the benefits of blending the two.

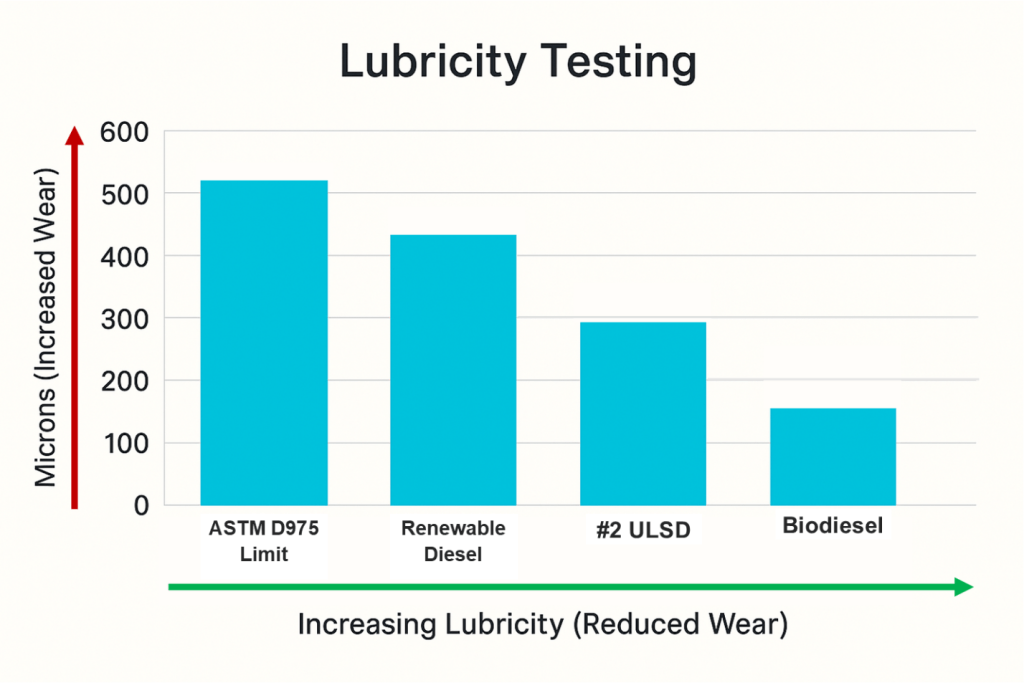

Renewable diesel has poor lubricity compared to petroleum diesel and biodiesel. Lubricity refers to the fuels ability to minimize friction and prevent wear between moving metal parts. Lubricity is critical to fleet performance because it helps protect the engine from damage by helping it run smoother, quieter, and cooler. Blending 1-2% biodiesel into renewable diesel and petroleum diesel has been shown to improve fuel lubricity, providing the necessary lubricity required.

Source: Graphic provided by the B20 Club of Illinois.

Blending renewable diesel and biodiesel can also help to lower emissions like particulate matter (PM), nitrogen oxides (NOx), carbon monoxide (CO), total hydrocarbons (THCs), and aromatic compounds. According to CARB and NREL data, an 80% blend of renewable diesel blended with 20% biodiesel can reduce particulate matter emissions by 29%, aromatic compounds by 39%, carbon monoxide by 23% and nitrogen oxides by 9% compared to petroleum diesel fuel. Similarly, a blend of 50% renewable diesel and 50% biodiesel produced 56% less PM, 53% fewer aromatic compounds, 30% less CO, and 6% NOx. Both fuels are also virtually free of sulfur, resulting in significant reductions in emissions of sulfur dioxide compared to petroleum- based fuels.